The basic principle of model-based diagnosis of technical systems is based on a quantitative mathematical model of the process to be monitored. The difficulty in the realization of such model-based diagnostic systems lies in the creation of the process model. For example, in process engineering, industrial processes, it is often only possible to set up a robust process model for feature generation with a great deal of development effort and detailed expert knowledge about the physical relationships of the process.Eine Alternative zu den analytisch modellbasierten Methoden bieten datengetriebene, lernfähige Modellansätze. In der Anwendungsklasse „Performance und Condition Monitoring von verfahrenstechnischen Prozessen“ werden Methoden des maschinellen Lernens / Data Mining bereitgestellt, welche es ermöglichen, auf Basis von „unüberwachten“ Lerndatensätzen geeignete Prozessmodelle zum Performance und Condition Monitoring zu generieren.

The ProDaMi-Suite provides various functionalities for performance and condition monitoring:

- Support for data-driven modeling of complex process engineering processes in the chemical industry:

Modelling of process behaviour based on historical process records using machine learning methods, especially for technical processes with slowly changing process behaviour (quasi-static process dynamics)

- Acquisition of process knowledge through structure-discovering data mining methods:

Recognition and description of process phases in process engineering production plants through structure-discovering "unsupervised" learning methods

- Online monitoring and diagnosis of process behavior:

Use of data-driven models for monitoring process behavior, monitoring of process parameters, detection of creeping changes in operating points.

Diagnosis of faults, component failures and localization (FDI)

Typical applications are continuous processes in the chemical / pharmaceutical industry. These processes are characterized in particular by the following characteristic properties:

- Continuous long-lasting processes for one product variant, e.g. column processes.

- Examples:

- Large-scale industrial production of basic materials for e.g. coatings, pharmaceutical products, etc.

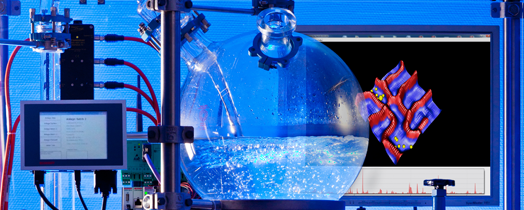

In addition to these large-scale chemical plants, the application class also covers batch processes in the chemical / pharmaceutical industry. The application class focuses on the following processes:

- Batch processes for the production of high quality chemical and pharmaceutical products in universal batch reactors

Examples:

Basic materials for pharmaceutical products, vaccines, pesticides, etc.

Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB

Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB