Successful and promising factory trial in Cleebronn

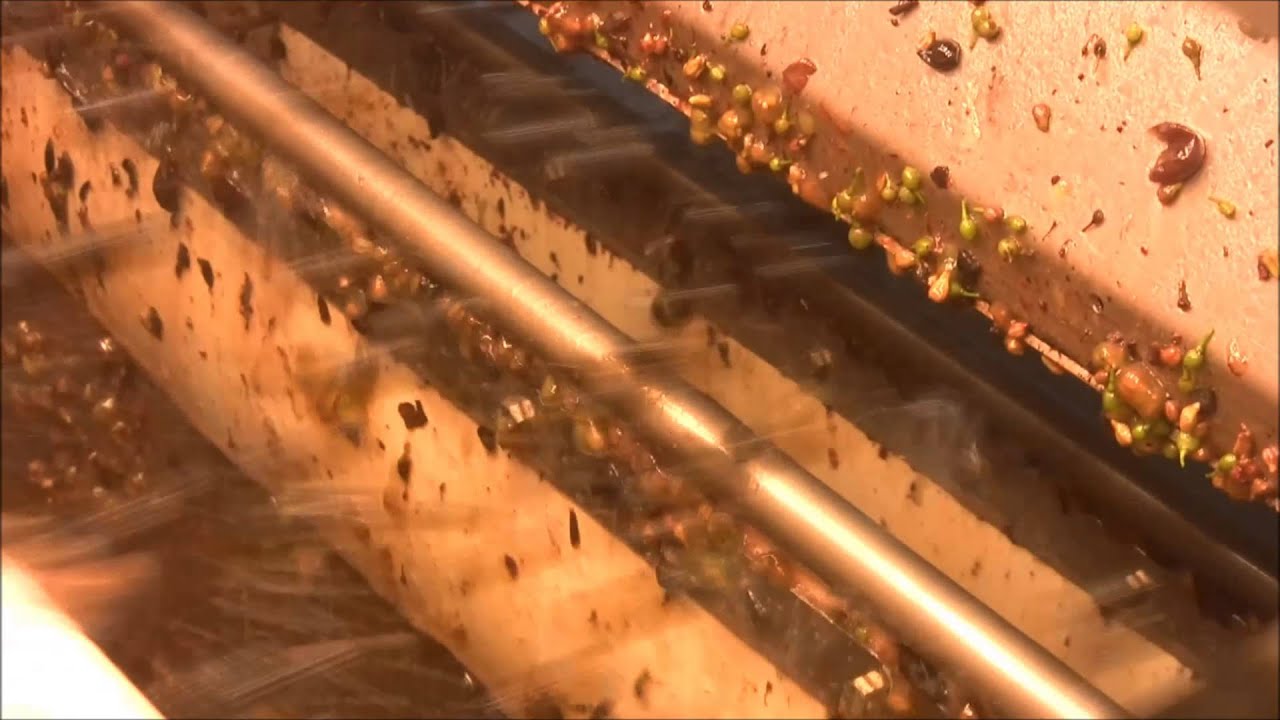

The new sorting module of the Fraunhofer IOSB was integrated as a component into the existing destemmer of the winery as part of a factory trial. After the harvest had arrived in the winery, it was immediately transported as usual to the destemmer for further processing, which separates the grapes from the stalks and separates the berries on a conveyor belt. On this conveyor belt, the grapes passed through the sorting module of the Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB, where the material flow is recorded by a line scan camera and the image is evaluated by a computer in milliseconds. The connected control for a battery of hydraulic nozzles causes the detected foreign material to be blown out by a targeted air blast. What the system is to evaluate as "bad" is taught in advance: vinegar berries, mould, stalks, scaffolding parts, combs, leaves, insects and incorrect degree of ripeness are common ejection criteria.

During this learning process, the system trains the shape and colour of the "fit" and "not-fit" parts, whereby the sorting is mainly done according to colour. Once learnt, it is stored and only needs to be adapted to the respective berry varieties. This makes it possible to relearn the changed parameters within 10-15 minutes if the grape variety is changed. The change between different grape varieties is therefore time-saving and simple.

In the first trial, the varieties Viognier, Riesling, Pinot Blanc, Lemberger, Trollinger and Cabernet-Dorsa were processed one after the other. All sorting results were immediately rated "very good" by the cooperation partners and the cellar master.

Project manager Dr. Kai-Uwe Vieth was very confident: "Already in the first trial, a throughput of 5 t/h was achieved, but we are aiming for a volume of approx. 8-9 t/h in the future". Vieth explains: "With this system a further increase in yield and quality can be achieved in the future. The vines can be completely harvested and only in the pre-processing stage is the harvest sampled and separated. In this way, even more productive top wines can be developed and premium batches can be expanded. The short time span of the harvest is optimally exploited by the high-tech support".

Sorting systems from the Fraunhofer IOSB are already in use worldwide in a wide variety of applications, whether in gold mining in Siberia, in South African diamond mines, used glass recycling centres or in coffee and tea sorting. New application ideas are constantly driving the researchers forward in their ideas.

Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB

Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB